Brick building material has been used as a form of construction for a long time due to its stability. It is assembled by placing bricks in mortar in an organized manner to erect solid mass that endure exerted loads. There are a number of types of bricks plus number of mortars which can be employed to build brick masonry.

The tie in brick masonry, which sticks bricks together, is formed by filling joints between bricks with appropriate mortar.

Kinds of Brick Masonry Work

- Brick Work in Mud

- The mud is employed to fill up different joints brick masonry work.

- It is employed for building of walls with maximum height of four meters.

- Brick Work in Cement

This kind of brick masonry is building by laying bricks in cement mortar to a certain extent than mud which is exercised in brick work in mud.

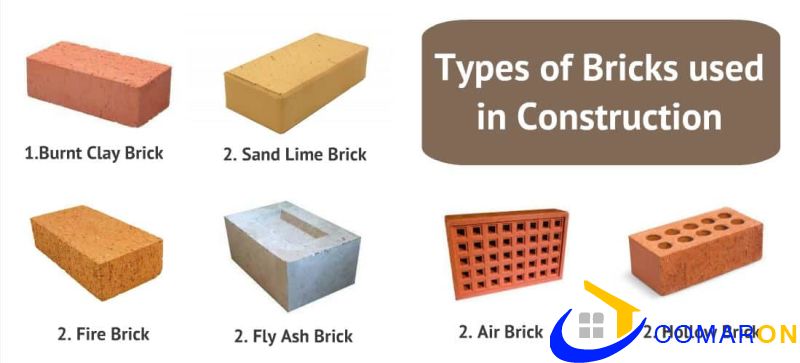

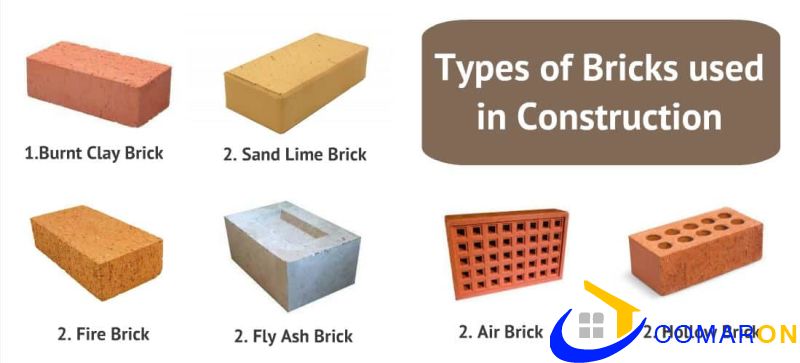

Kinds of Bricks

There are different kinds of brick used in the construction of brick masonry which take in:

- Concrete Bricks

- Common Burnt Clay Bricks

- Fly ash Clay Bricks

- Sand Lime Bricks (Calcium Silicate Bricks)

- Engineering Bricks

- Other Brick Types comprise bullnose, cownose, channel, coping in addition to hollow bricks.

- Concrete Bricks: Concrete bricks are made from a mixture of cement, sand, aggregate, and water. They are solid and commonly used for various load-bearing applications in both residential and commercial constructions.

- Common Burnt Clay Bricks: These are traditional bricks made by molding clay and firing them in a kiln until they are hardened. They are widely used in construction and have been used for centuries.

- Fly Ash Clay Bricks: These bricks are made using fly ash, a byproduct of coal combustion, mixed with clay and fired at high temperatures. They are more environmentally friendly than traditional clay bricks and possess good strength and durability.

- Sand Lime Bricks (Calcium Silicate Bricks): These bricks are made from a mixture of sand, lime, and water. They are molded under pressure and then cured in an autoclave to enhance their strength. Sand lime bricks offer high strength and excellent resistance to moisture.

- Engineering Bricks: Engineering bricks are specially manufactured bricks designed for their high compressive strength and low water absorption properties. They are commonly used in civil engineering projects, where durability and load-bearing capacity are essential.

As for the other brick types you mentioned:

- Bullnose bricks: These bricks have rounded edges on one or more sides, providing a smooth, curved finish to structures.

- Cownose bricks: Similar to bullnose bricks, cownose bricks have a rounded edge, but they are shaped like a half-circle on one side and straight on the other.

- Channel bricks: These bricks have a U-shaped indentation running along their length, which allows them to be used as water channels or for creating decorative patterns.

- Coping bricks: Coping bricks are designed for capping walls or parapets, providing a protective and decorative finish.

- Hollow bricks: Hollow bricks have voids or holes that reduce their weight and improve insulation properties. They are used for non-load-bearing walls and for thermal insulation purposes.

Each type of brick has its specific applications and advantages, and their choice depends on the requirements of the construction project.